An unique product of a small Czech company helps the largest private space research corporation to increase the stability of rocket engines

Current space rocket vehicles use the oxidizing component of pure liquid oxygen, which needs to be distributed through pipelines, valves and other metal components. Not only in the rocket industry, it is a well-known fact that metal surfaces that come into contact with pure oxygen under high pressure must meet extremely strict surface cleanliness requirements. A clean surface, free of organic greasy substances, e.g. oils, emulsions and lubricants, significantly reduces the extreme risk of unexpected and difficult-to-detect violent reactions, including spontaneous combustion and explosion.

Imaging technology, developed by a small Czech company, TechTest, s.r.o., has enabled the currently largest private manufacturer of rocket technology for peaceful space research in the US to supervise in real-time, step by step and in the final phase decide and approve the surface condition of components critical to stable operation of rocket engines from in terms of the occurrence of dangerous contamination.

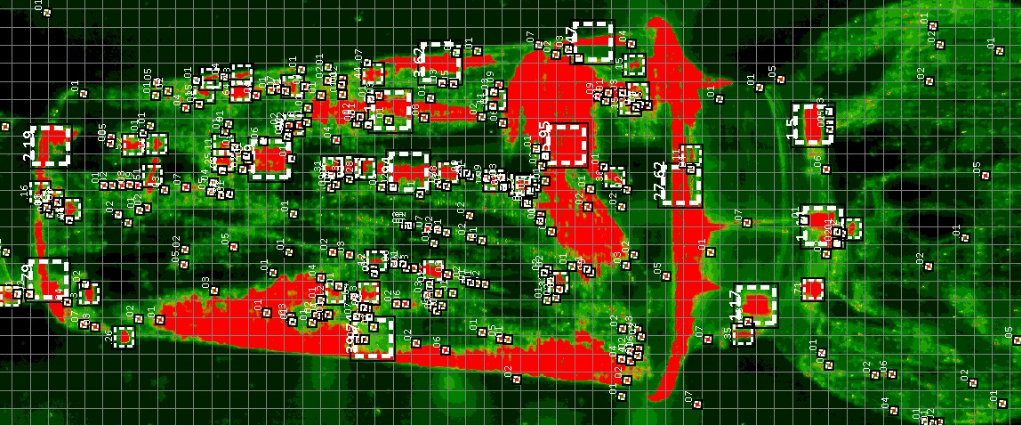

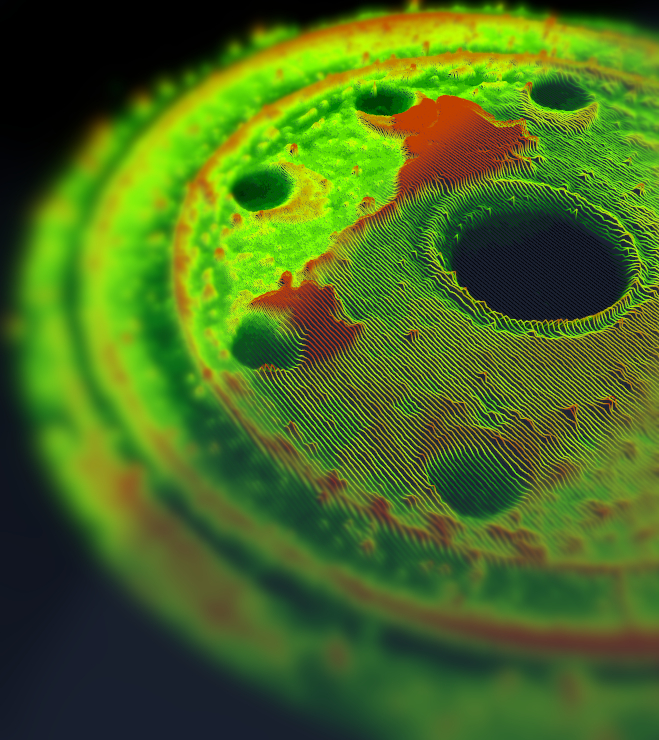

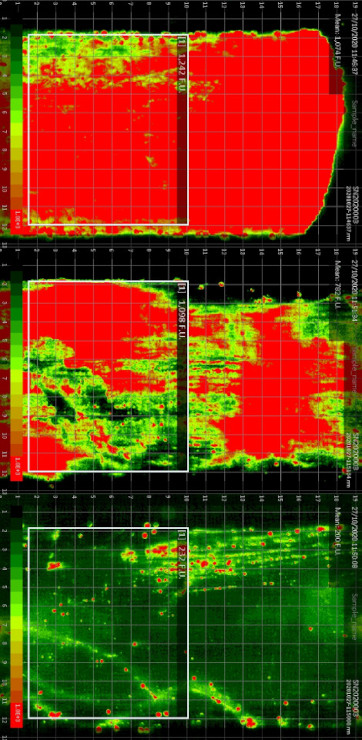

A very sensitive fluorescence detector is a part of the imaging technology, which detects on the surface of precision parts, visualizes and quantifies the occurrence of the smallest undesirable residues of organic oil and grease substances by the means of image processing. The residues can be in the form of adhering machining emulsions, temporary preservative layers, fingerprints, microscopic droplets of aerosol oils, residues of cleaning media after imperfect rinsing, etc.

Thanks to this detailed analysis, only those parts will be released for subsequent assembly that have met the very strict requirements for the distribution of local residues and at the same time have not exceeded the maximum limits of their surface concentration. In addition, the detector excels in unprecedented sensitivity, and when using all possible methods of degreasing and cleaning, places can always be found on the surface that show an increased incidence of undesirable substances.

The main benefit of Recognoil® imaging technology is, above all, the very fast finding of the cause of contamination, the possibility of repeating and optimizing cleaning processes. Unlike time-consuming laboratory methods, this new technique allows the final evaluation of the state of surface cleanliness in near real time.

The advantage of the technology is its economic availability and it can be very effectively applied not only in the high-tech environments of the world's largest companies. Recognoil® products have already found their way into several dozen Czech and European companies, where they help to optimize cleaning processes, prevent hidden surface defects and thus save costs associated with complaints and the risk of losing the customer.